Battery top cover chip defect inspection machine

Case category

Battery top cover chip defect inspection machine

Customer Requirements

Detect defects in the battery top cover patch, sort out qualified and defective products, detect fast and accurately, and improve efficiency.

Our programme:

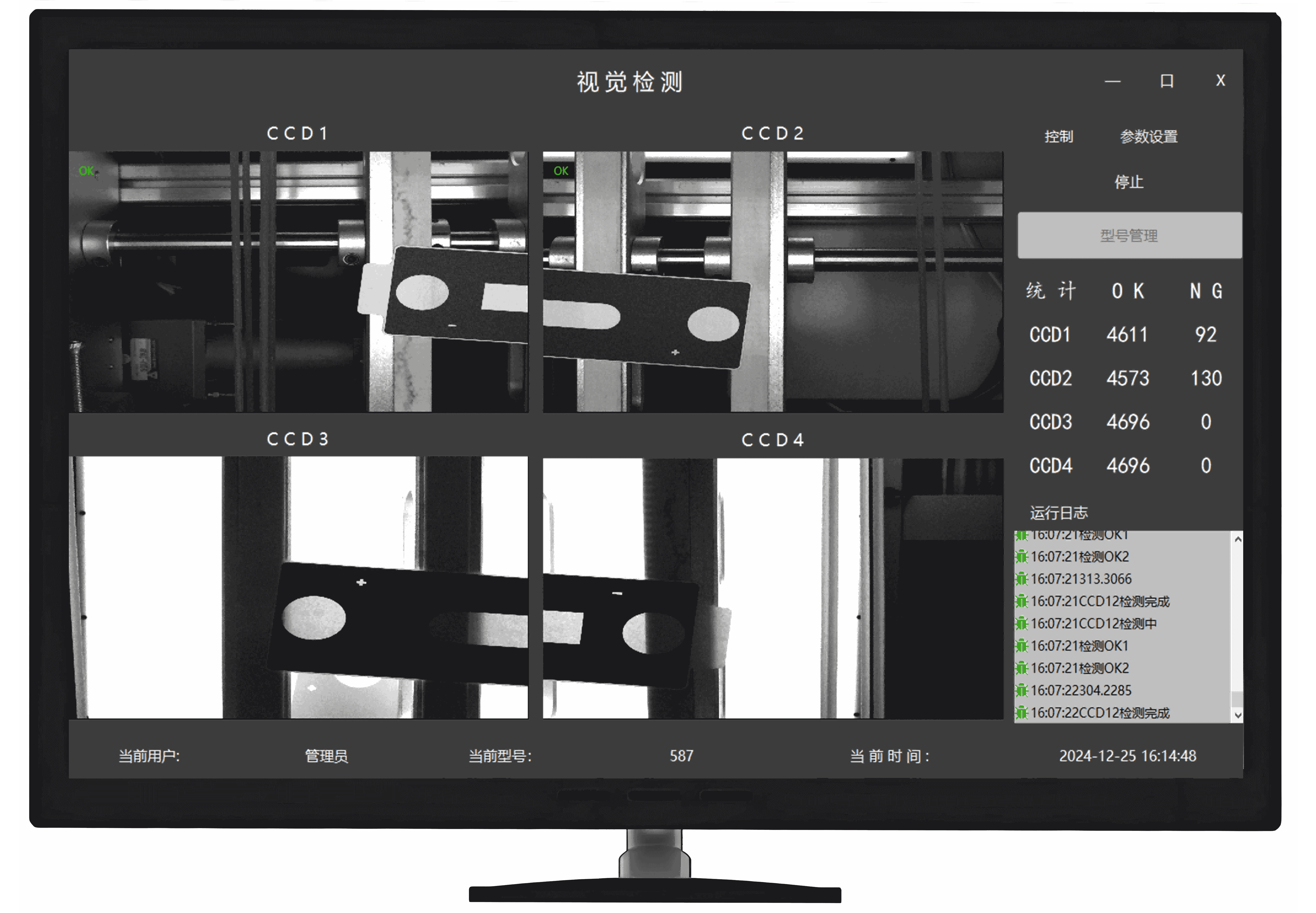

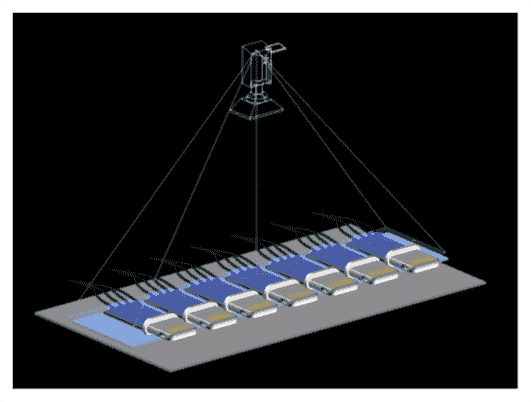

1.Vision detection principle:

①Image Acquisition: The optical system acquires the image, converts it into digital format and transfers it to the computer memory.

② Image Processing: The processor applies different algorithms to improve the image factors that have an impact on detection.

③ Feature extraction: the processor identifies and quantifies key features of the image, such as position, number, area, etc. This data is then transferred to the control programme.

④ Discriminate and control: the processor's control program makes conclusions based on the received data. For example, whether the position is in specification or not, or how the actuator moves to pick up a part.

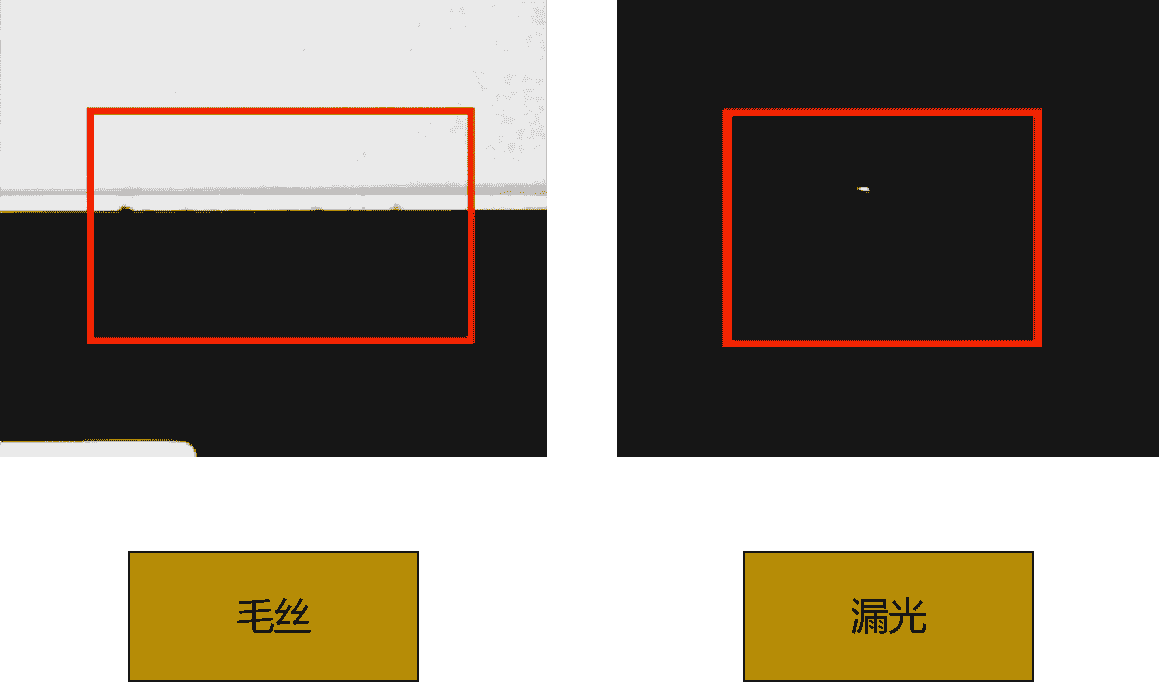

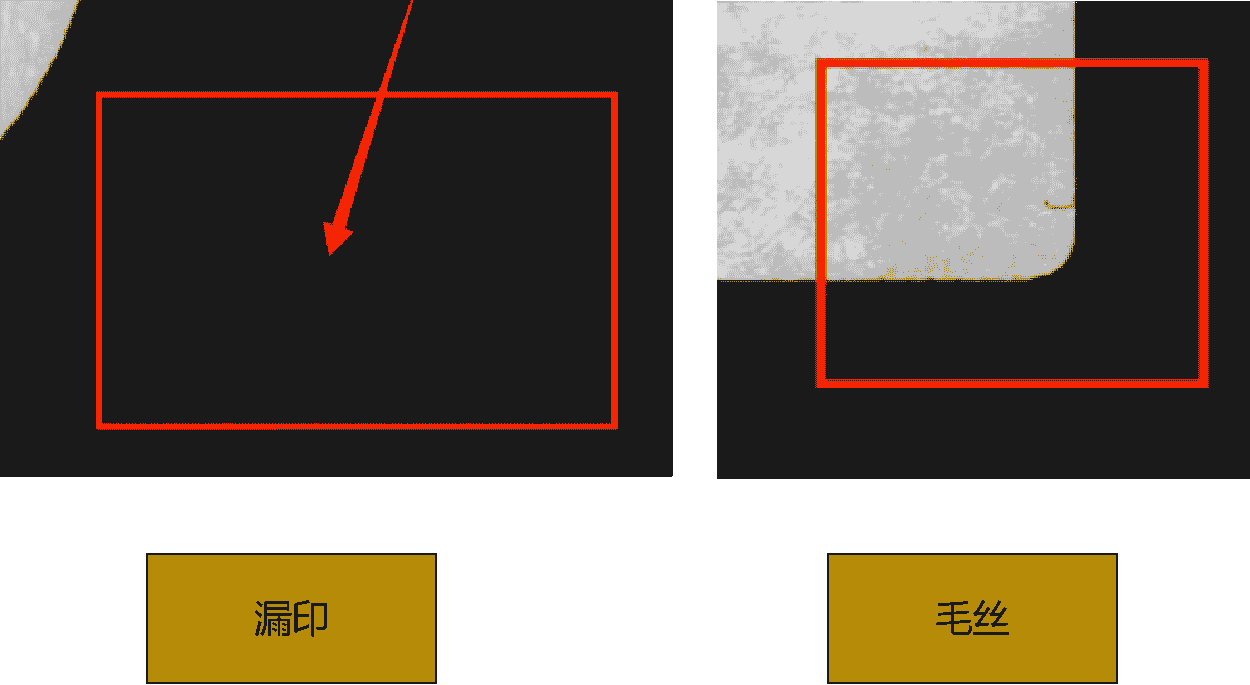

2. Types of product defects:

Plugged holes, fuzzy missing, creases and indentations, scratches, oil impurities, residual glue filaments, joints, surface dents and bumps, bumps and packages broken and leaking light;

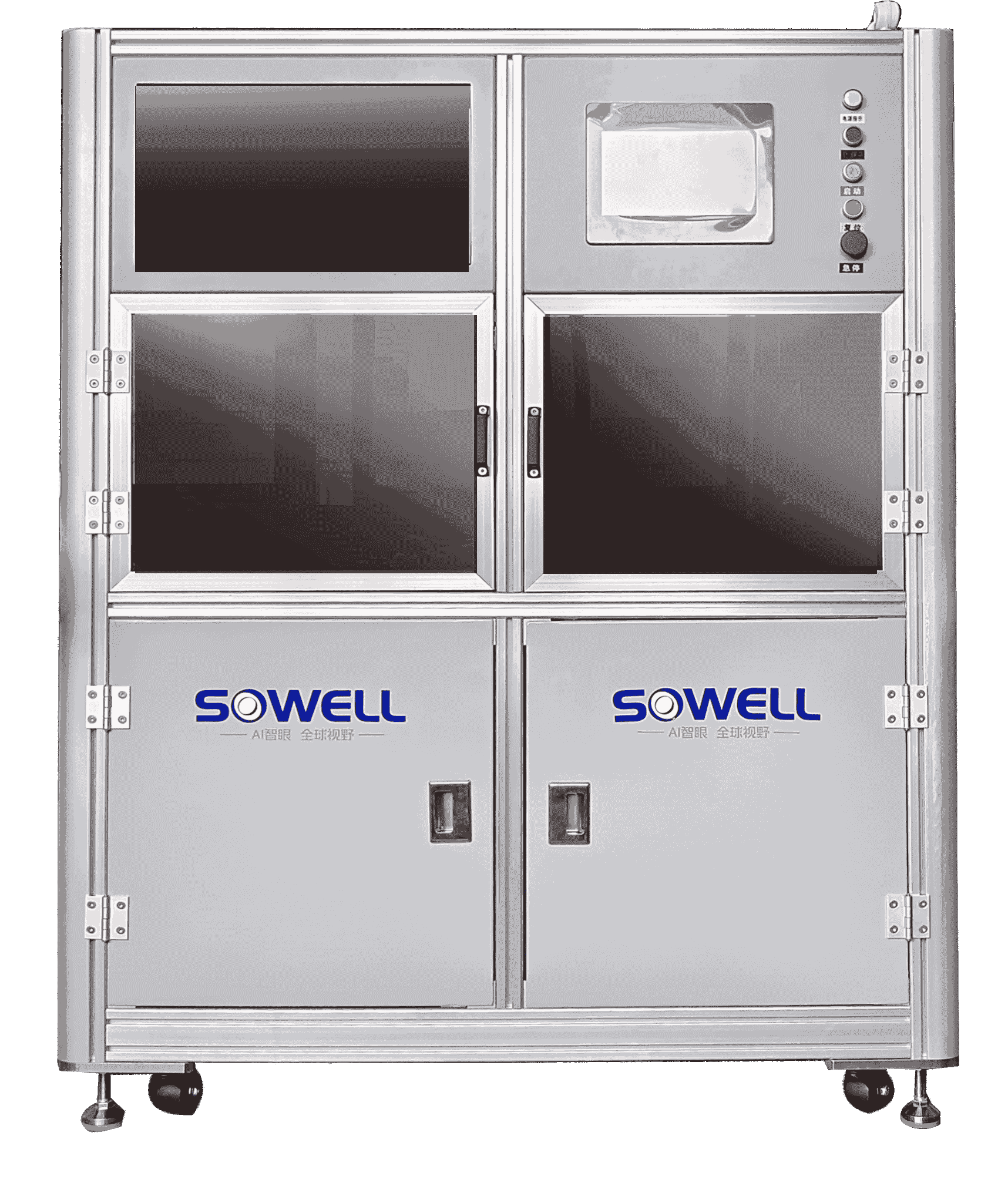

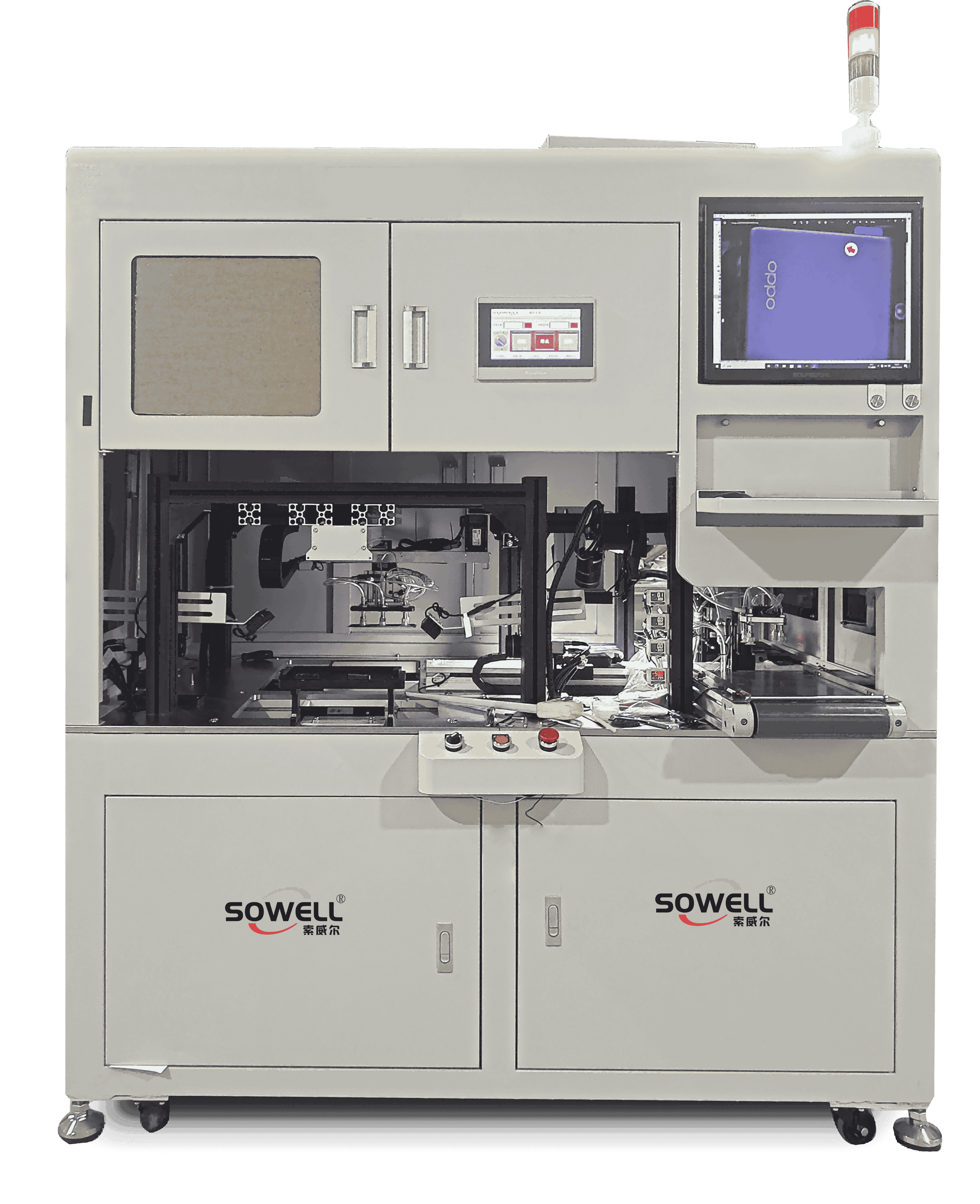

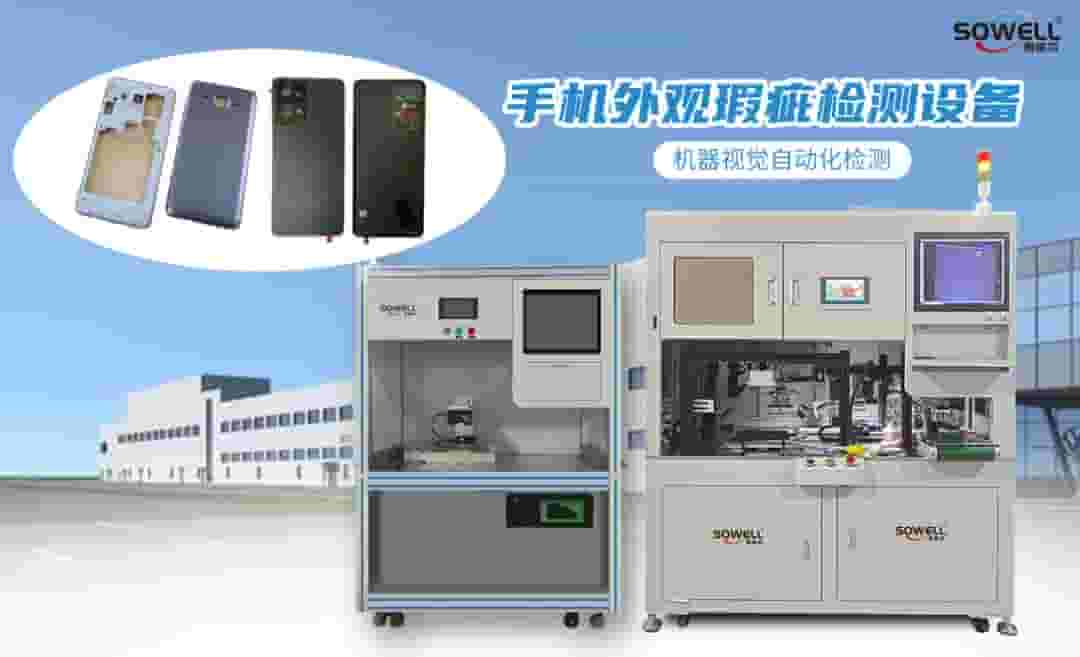

3. Equipment and software

Back to list

Back to list